Hoegaarden

Hoegaarden, Belgium

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/projects/Hoegaarden/arquid_reference-sheet_HOEGAARDEN.png)

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/projects/Hoegaarden/hoegaarden.png)

Project info

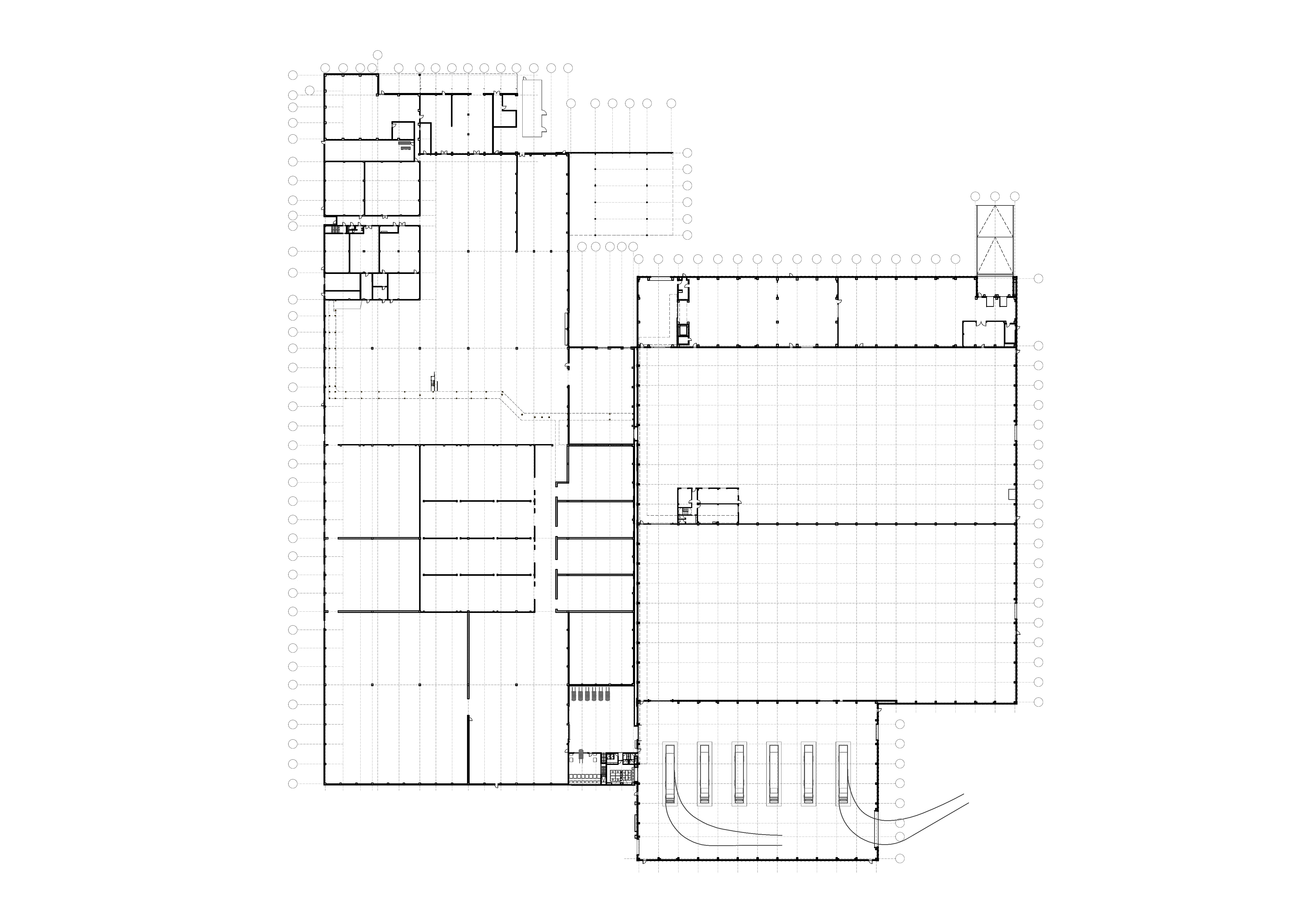

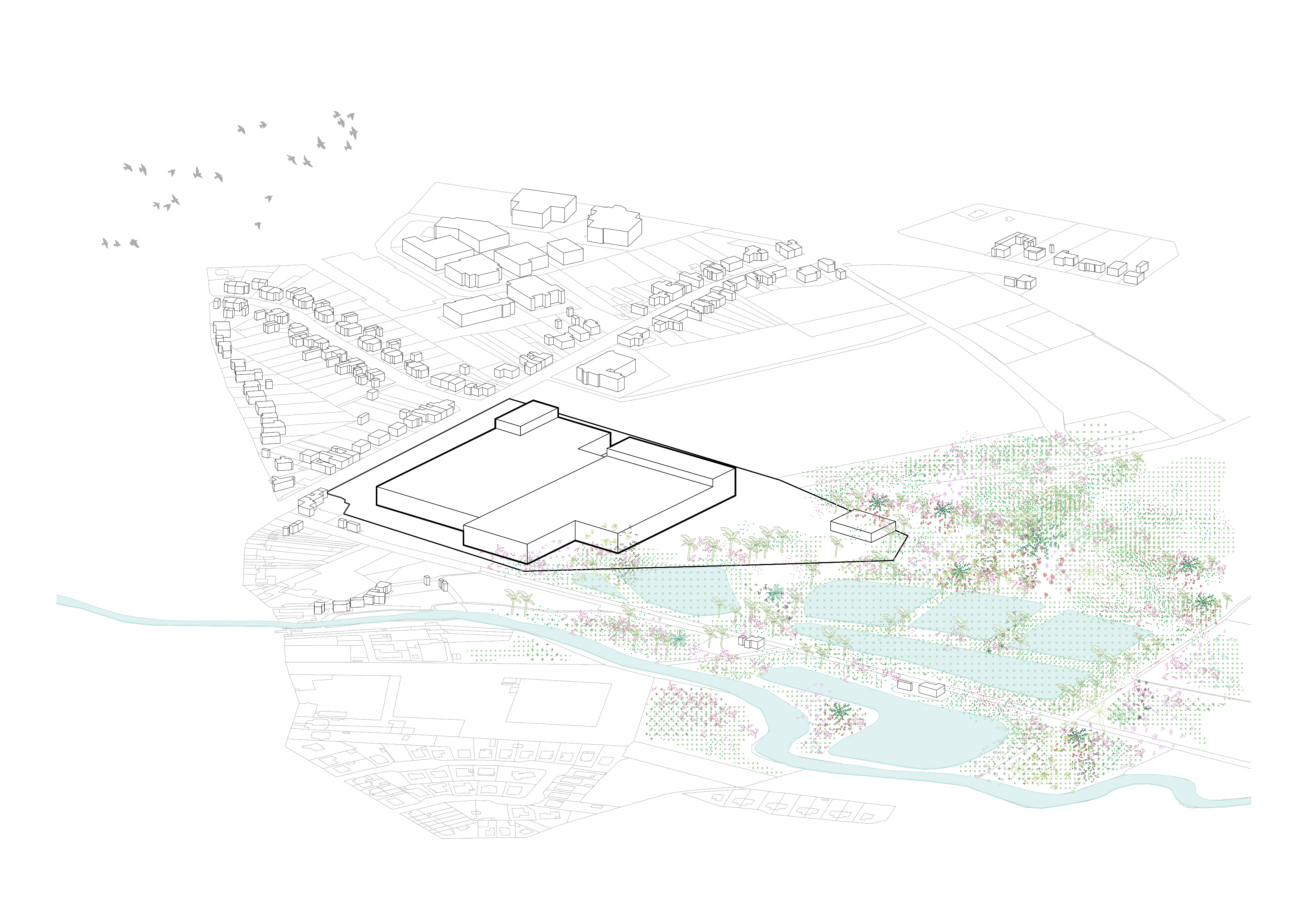

The project in Altenaken is part of an European masterplan designed for ABInBev which implies the intervention on the famous wheat beer Hoegaarden packaging plant, located in the Belgian town where it was born and which bears the same name.

This 20.000 m2 new building contains the extension for the packaging line and the new associated logistic facilities.

| Client | ABInBev Belgium |

| Project Management | IPS Belgium |

| Architecture | Arquid |

| Civil Contractor | Edibo |

| Precast Panels Supplier | Schelfhout Beton |

Challenges

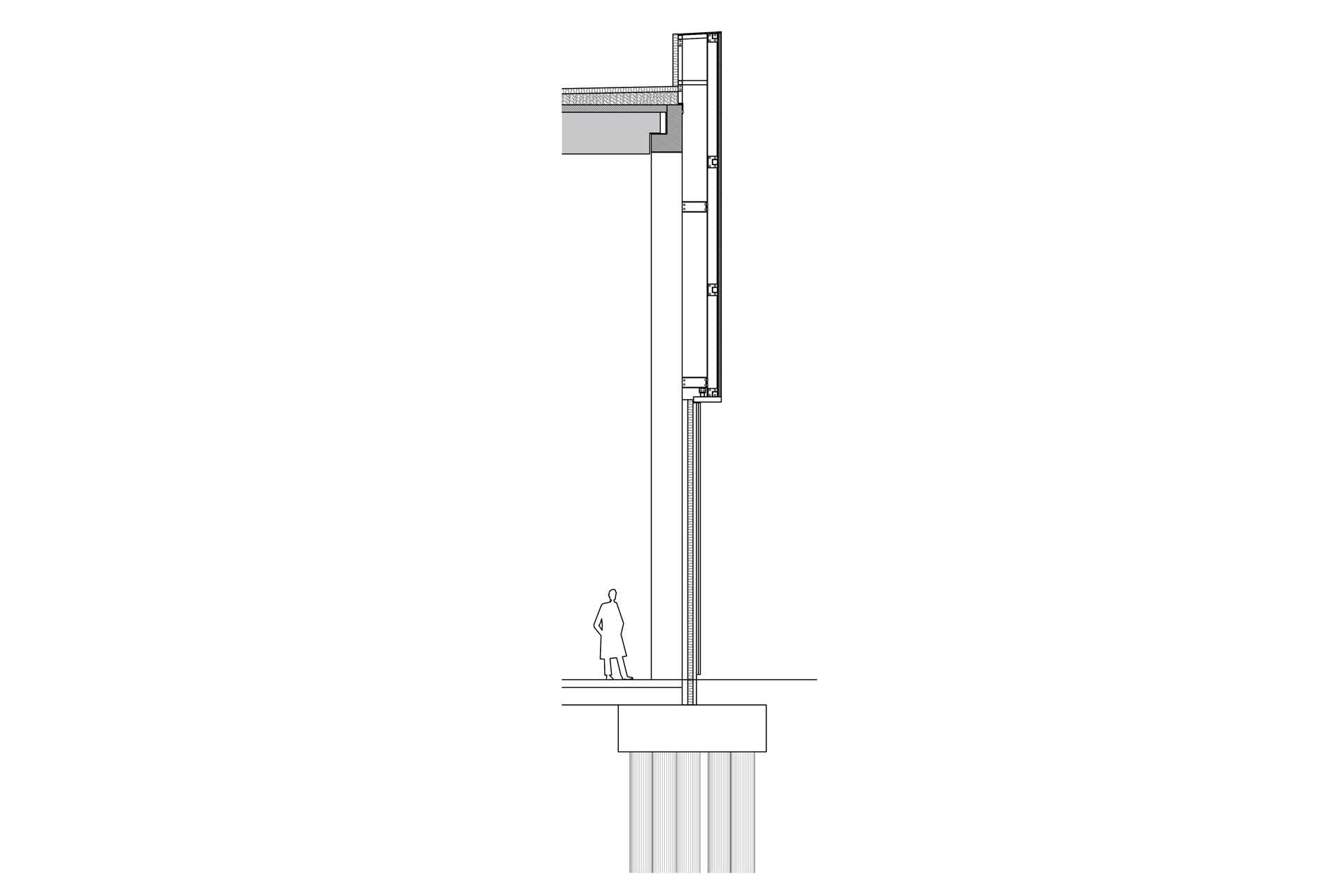

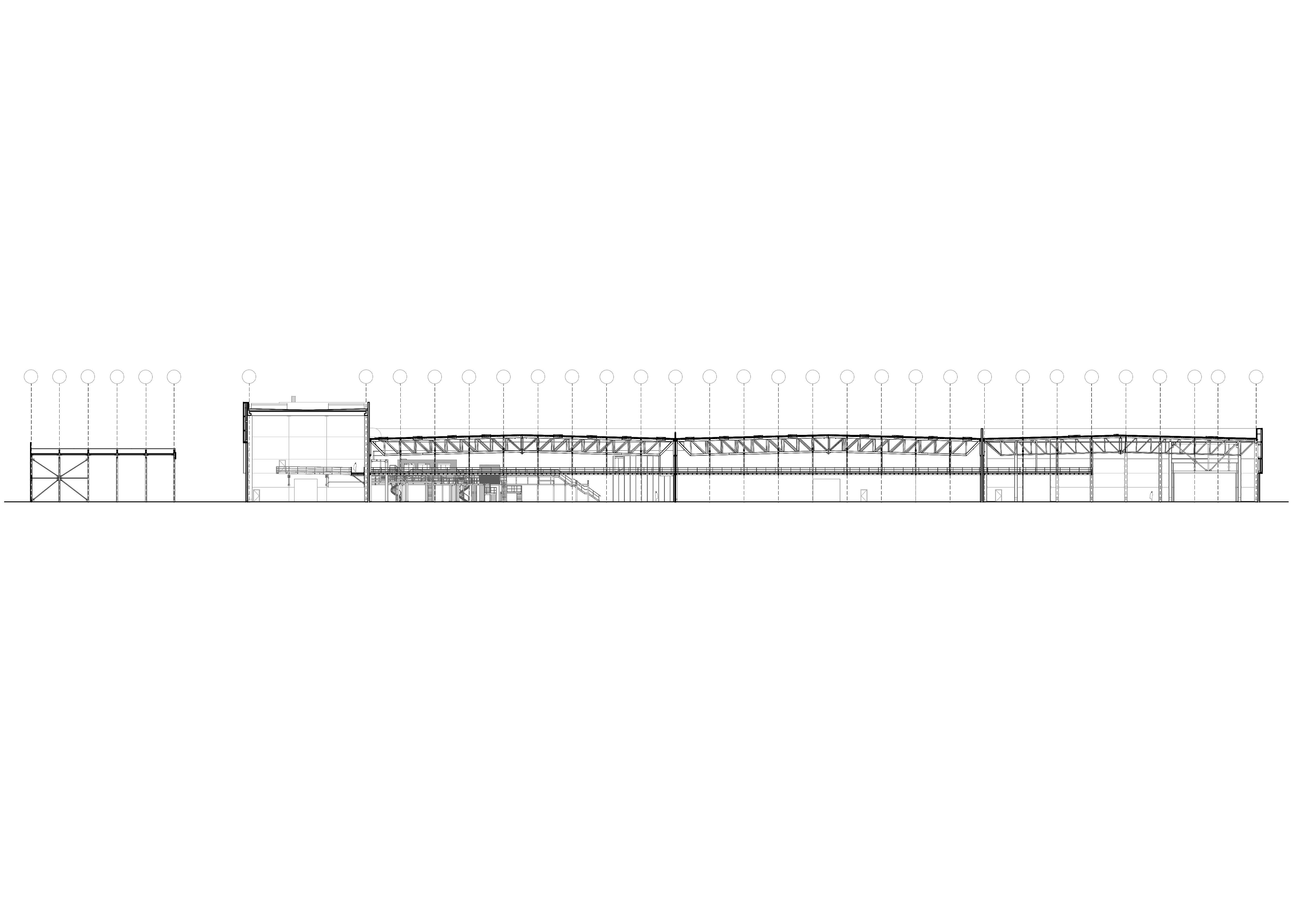

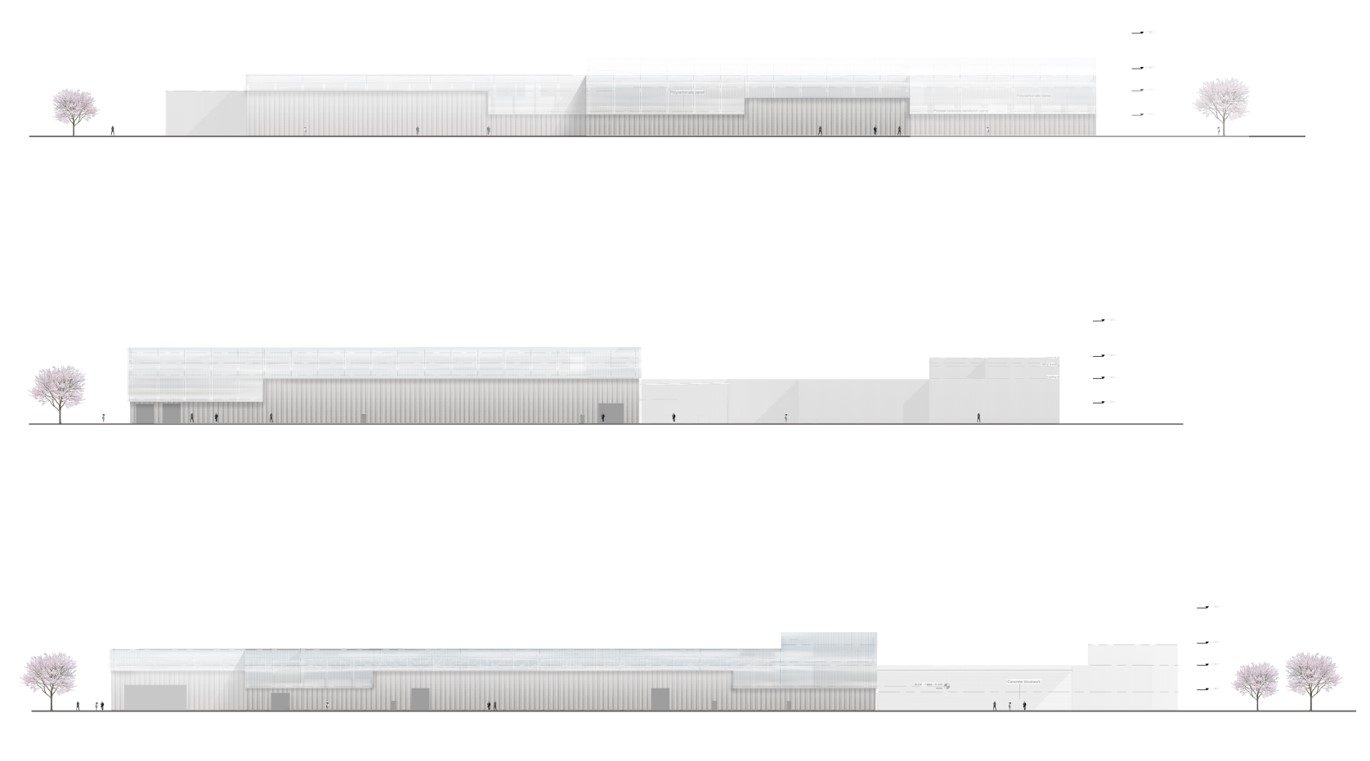

The facade became a very important point of design during the design phase in order to bring an added value to the new facilities and a renovated look.It is developed with the combination of three materials: concrete, sandwich panels and polycarbonate.

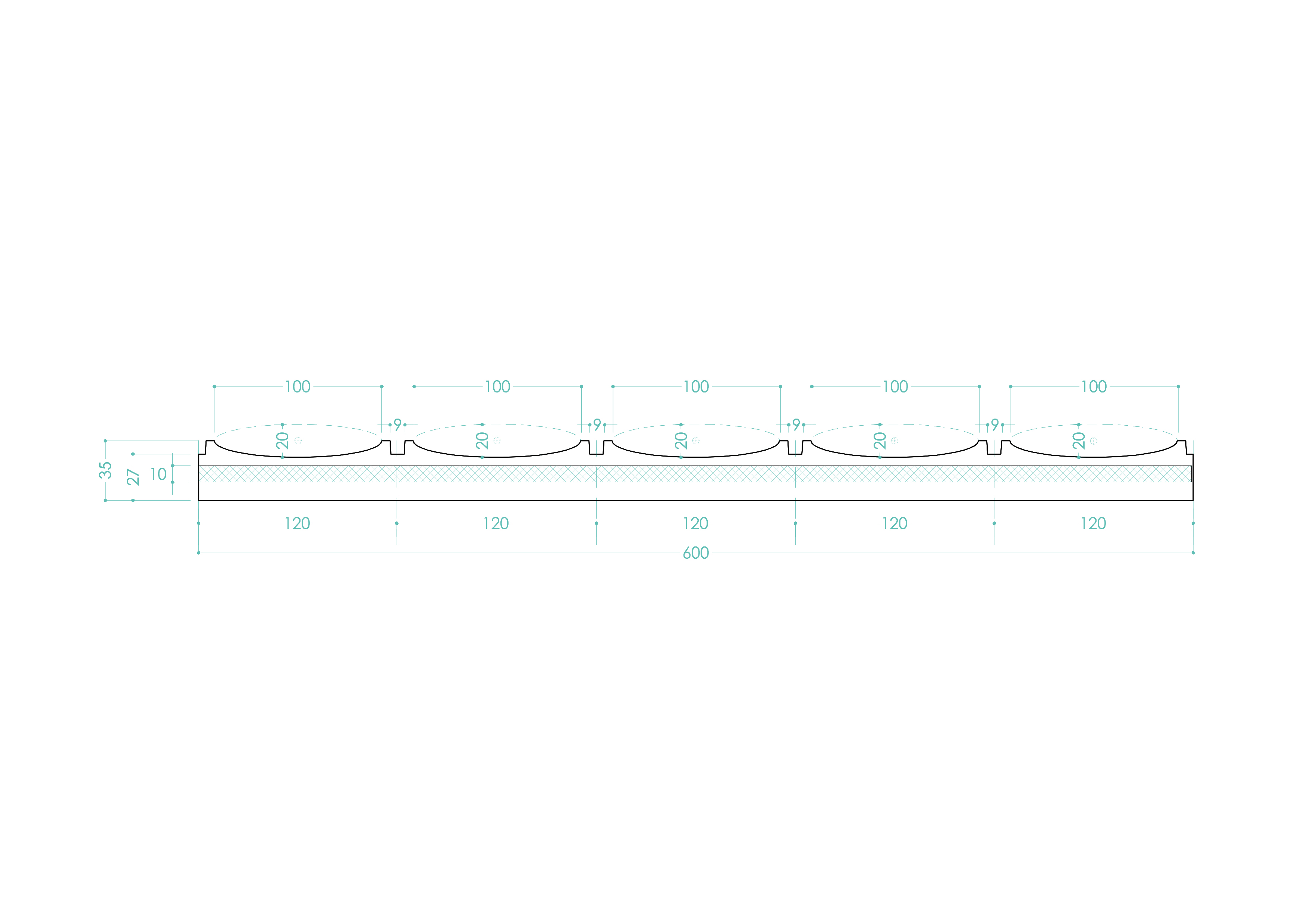

The concrete panels were conceived as unique and customized pieces for this specific project, and their design process was no small feat. In order to ease prefabrication and achieve an optimal technical performance, the panels needed to be as shallow as possible and follow a horizontal division according to the assembly certification in Belgium. However, from an architectural point of view, depth and shadows were important for creating the desired visual effect. A format that incorporates a 90-degree angle at the edge is chosen and verticality is emphasized through a 9cm joint between each curve of the panel. This way, the strong vertical shadow line is highlighted and the horizontal divisions become less visible.

In addition, the strong regulation on all industrial buildings in terms of fire protection leads to opting for an integrated, non-invasive solution in accordance with the philosophy of the project, which reflects the interior compartmentalization of the building. A white sandwich panel strip or 'tongue' is incorporated, not only because of its technical and safety condition, but because it helps to create volumetric variations on the facade through light and shadow.

On the other hand, polycarbonate, the softest and most permeable element, helps natural light flow into the factory during the day and lets the world know that the factory is still up and running at night (the company packs beer 24/7)!

Approach

The choice of thee three facade materials and the dialogue between them are not random at all, as this is the key feature in the design of the new packaging plant.

It is designed as a reminiscence to the beer brand's iconic glass thanks to the choice of materials and their shape:

Translucent anti-glare polycarbonate panels and white sandwich panels and the small cantilever over the concrete panels resembles the foam bubbles and replicates the head top of the glass. In the other hand, the concave shape of the concrete panels represents the beer glass itself.

Result

Inside, the natural light that is filtered through the polycarbonate panels is carefully treated by the choice of light-colored materials and large double-height spaces.

The large packaging, storage and expedition areas follow the same scheme where the deck and the entire metal structure of trusses and purlins are lacquered in white in order not to lose that feeling of clarity and spaciousness.

Similarly, the small office block located inside the factory is limited by white sandwich panels and defined with a neutral and elegant atmosphere that follows a clean and neat aesthetic. Visual distractions that may block workers' concentration are minimized.

![[Translate to English:] [Translate to English:]](/fileadmin/user_upload/projects/Hoegaarden/Hoegaarden_First_Shooting_Noceto_web_04.jpg)